The A+X Balanced Flowmeter was originally developed for the National Aeronautics and Space Administration’s (NASA) Space Shuttle Program to measure the liquid oxygen and hydrogen fuel of the main engine. We have successfully commercialized the technology to many different industries, including Chines National Space Administration (CNSA). All five major Space Lauch Center in China have our flowmeter products installed for accurate measurements and guarantee successful rocket launches.

Harvesting the power of nuclear fission and turning mass into energy results in very high temperatures and pressures, which needs to be monitored and adjusted very precisely. A+X Flowmeters have consistently delivered exceptional performance both inside and outside the nuclear island, while ensuring full compliance with all regulatory safety standards.

A+X Flowmeters are widely used in petrochemical and coal-chemical plants for their ability to handle harsh conditions (high temperature, pressure, corrosive fluids), making them durable and low maintenance. We offer cost-effective flow measurement solutions for many fluids and pipe sizes, which fit easily into existing systems. The simplicity, reliability, and compliance with industry standards make A+X product a practical choice for demanding chemical processes.

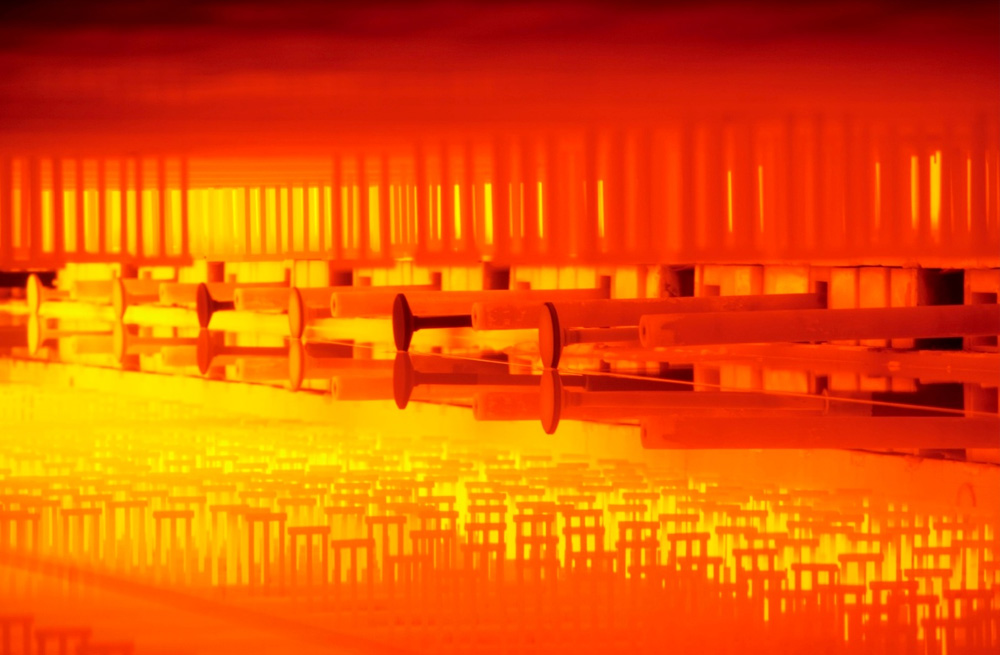

A+X Differential pressure flowmeters are used in metallurgy for their ability to withstand extreme heat, abrasion, and corrosive media, from molten metal to furnace gases, while delivering precise flow control. Trusted for cooling systems, combustion regulation, and temperature monitoring, A+X Flowmeters balance rugged durability with cost-effective performance in metallurgy industry.

To achieve the best glass production, the flow of the glass and the gases needs to be controlled very precisely. Not only the flow rate, the temperature and humidity are also important aspects to controlling the production. A+X Flowmeters provide the industry with leading solutions to gases measurement.

In most powerplants, the transformation into electricity is done through steam generated by a heated-up boiler to powered turbine. A+X Flowmeters are an excellent choice for measuring the flow of the steam, with their ability to measure hot steam precisely and with very little total pressure loss, without impacting the efficiency of the generator.

The deep cryogenic air liquefaction and separation is a challenging application. Low-temperature liquids are prone to vaporization under pressure reduction. The A+X Balanced Flowmeter, utilizing a multi-hole balanced structure, minimizes permanent pressure loss, thereby significantly reducing liquid vaporization compared to conventional solutions.

In municipal gas, heating or water networks A+X Flowmeters are a great choice because of their high accuracy, low cost, minimal pressure loss, and easy maintenance. With very short straight flow requirements they can easily be installed in preexisting pipes without the need for new planning.

A+X Ultrasonic Flowmeters are ideal for gas distribution and pipelines due to their non-intrusive design and wide measurement range. Their industry leading accuracy, even in large-diameter pipelines, is critical for custody transfer and billing. They handle varying gas compositions (natural gas, biogas) and provide real-time data collection and leak detection, making them the smart choice for reliable, long-term gas infrastructure.

Copyright © 2025 Keyontechs Co.,Ltd.