A+X nozzles are designed and manufactured in accordance with ISO 5167-3. It is mostly used for high speed flow measurement.

Standard Specifications

● Pipe size: 50mm~500mm

● β value range: (0.3≤ β ≤0.8)

● Reynolds number range:

When 0.3≤ β <0.44, 7x10^4≤ ReD ≤10^7;

When 0.44≤ β ≤0.8, 2x10^4≤ ReD ≤10^7

Long radius nozzle: 10^4≤ ReD ≤10^7

● Uncertainty:

Nozzle uncertainty is ±0.8~1.2% when not calibrated

The uncertainty of long-diameter nozzle is ±2%.

The calibrated uncertainty can reach ±0.5% -1.0%

● Repeatability: ≤ 0.15%

● Permanent pressure loss: 25%~92% of differential pressure

● Operating temperature: -196 ≤ T ≤ 700°C

● Working pressure: according to ANSI/HG20615 and DIN/HG20592 flange standards

● Pressure tapping specifications:

1/4 "NPT or PSW

1/2 "NPT or PSW

1 "or 2" pressure connection flange

● Conventional materials :304, 316, 321, etc.

● Standard material: 304, 316, 321

● Customized materials: Hastelloy C-276, Monel 400, Inconel, more available upon request.

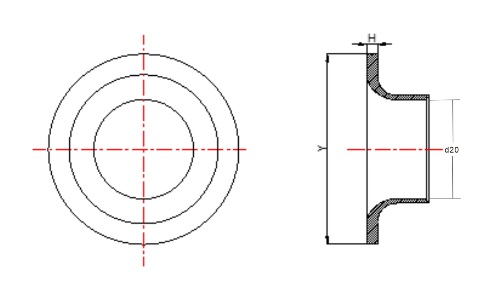

Nozzle Flow Element

Nozzle throttling element is the core measuring element of a nozzle flow meter.

Size: DN50 – DN500

Pressure: CL150-CL2500, PN2.5-PN160

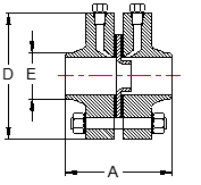

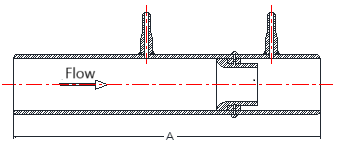

ANFF Wafered Type

● The flow element is wafered by the flange.

● Most consistent with the traditional installation of the structural form.

● Avoid the problem of mismatch between flange and flow element on site.

● Simple structure and easy maintenance.

● The data is based on ISA1932 nozzle

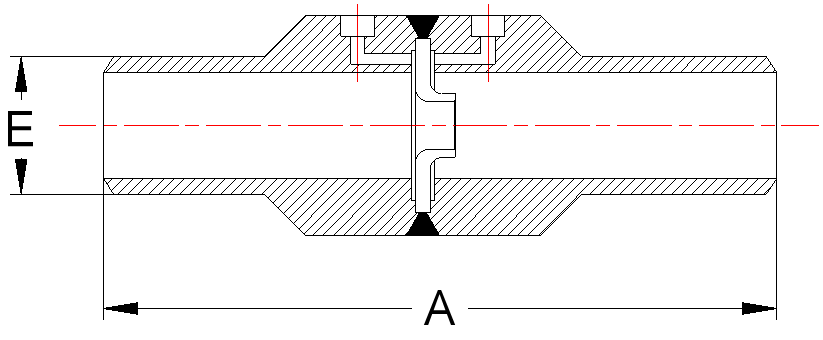

ANFW Welded Type

● The flow element is inside a segment of pipe, which is then welded to the pipeline, this installment is firm and reliable.

● Welding structure, prevent leakage.

● Good concentricity between nozzle and tube segment to ensure measurement accuracy.

● Suitable for high temperature and high-pressure applications.

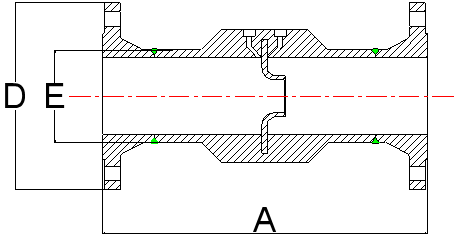

ANPP Flanged Type

● The flow element is inside a segment of pipe, which is then connected with the process pipe by flange. The inner diameter of the pipe section is precisely machined to meet the technical requirements of nozzle throttling device.

● High measurement accuracy.

● Good concentricity, good consistency with the design instrument diameter.

● Connected with process pipe flange, easy to install.

ANET Welded Long Radius Type

● Welded long radius nozzle flowmeter conforms to the GD2000 technical requirements, mainly used in power plant boiler supply water and steam.

● Welded pipe structure.

● Long radius nozzle embedded installation, avoid faulty weld

● Low pressure loss, long life, wear resistance.

Copyright © 2025 Keyontechs Co.,Ltd.