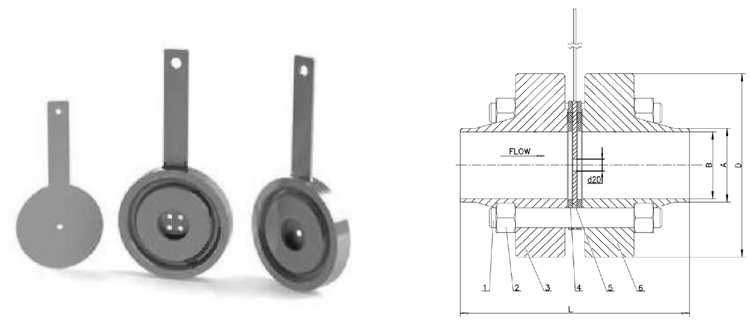

Single-Stage Restriction Orifice

A restriction orifice is used to reduce the pressure or the flow in the pipeline.

The restriction orifice enables precise fluid control by creating a constriction in the flow path to throttle the fluid. The working principle is based on Bernoulli's principle: when fluid flows through a narrow constriction, its velocity increases while pressure decreases.

By selecting the size and shape of the orifice plate, engineers can accurately control the flow rate and pressure drop across the plate.

Restriciton plate has simple structure, high reliability, and outstanding cost-effectiveness.

Restriction orifice is designed and manufactured according to ISO5167, AGA-3, RW Miller.

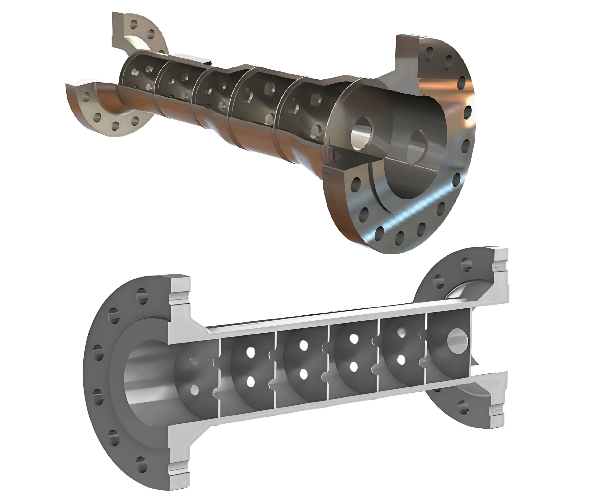

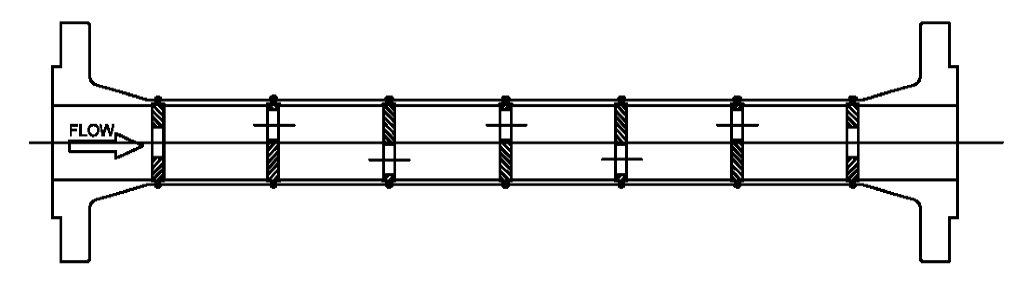

Multi-Stage Restriction Orifice

When a liquid needs to have large pressure drop, cavitation or flushing may occur. And in case of gas, a large pressure difference can cause chocked flow. Multiple stage restriction orifice assembly may be required to achieve the desired pressure drop whilst preventing problems such as cavitation, flashing and high noise and vibration levels.

Cavitation is a potentially damaging and erosive condition which occurs when the internal pressure of the liquid passing through the orifice falls below its vapor pressure and vapor bubbles form. Further downstream from the orifice the pressure recovers sufficiently to collapse the bubbles with extreme violence. Cavitation calculations are performed during the design stage of a Multistage RO to calculate cavitation factors at each stage in the orifice assembly.

Flashing is a similar phenomenon to cavitation except that the process pressure never recovers sufficiently to collapse the gas bubbles resulting in two phase flow - liquid and gas – downstream of the orifice. Erosion of pipe work and valves and other instrumentation can occur due to the impact of liquid droplets carried at high speed in the vapor flow.

Choked flow in gases – also known as critical flow – occurs when too large a pressure drop is attempted across a single orifice plate. When the flow through the orifice becomes sonic, no further increase in flow can be achieved by either increasing the upstream pressure or lowering the down-stream pressure. A multistage RO will enable staged reductions in pressure to prevent choked flow occurring. A+X Multistage Restriction Orifices are manufactured from a wide range of materials and are engineered to meet specific project process conditions and requirements.

Copyright © 2025 Keyontechs Co.,Ltd.